We appear to be entering an era of electrified transportation, with everything from scooters to motorbikes, sports cars, school buses, trucks, trains, and even airplanes running on batteries. This is due to the rapidly declining cost of lithium-ion batteries and their improving performance. Better batteries make an expanding range of electric personal, light-duty, and heavy-duty vehicle technologies possible. A significant flow of retired or used batteries will inevitably result from the expansion of lithium battery deployments. Analysts estimate that over 2 million metric tonnes of batteries per year or over 500,000 automobiles might be retired by 2030.

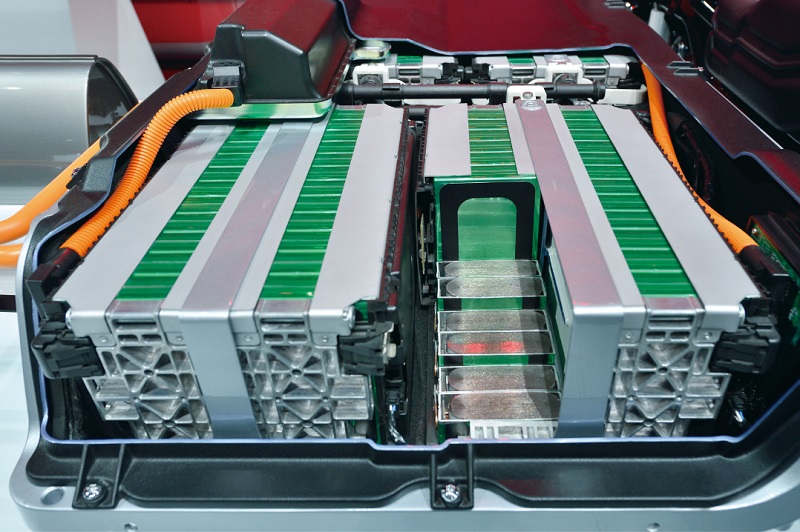

The automobile market still only includes a small number of electric vehicles (EVs), and the few batteries that are retired from vehicles are either being stored or investigated in various pilot-scale applications. Lithium batteries include valuable metals and other materials that can be collected, processed, and utilized to produce more batteries, in contrast to the majority of consumer electronic trash that has traditionally been headed for the landfill.

There are numerous viable approaches to lithium-ion battery recycling, but logistical, economic, and technical challenges need to be overcome. This is a summary of the situation of battery recycling today, highlighting prospects to recycle battery materials entirely and build a long-lasting value chain for lithium batteries.

Overview of the End of Life

Battery systems must be processed when an electric car is taken off the road due to an accident or aging. Reuse or repurposing (“second life”), materials recovery (recycling), and disposal are possible end-of-life options for used electric car batteries after their initial usage in a vehicle. Batteries eventually need to be recycled or disposed of, whether reused or not. To minimize the adverse environmental effects of incorrect disposal, take into account the advantages of recovered materials, and prevent the mining of resources, it is essential to understand the opportunities and barriers to recycling.

Today, pyrometallurgical, or smelting, methods are used in a small number of large-scale plants to recycle lithium batteries. These facilities burn out impurities and recover cobalt, nickel, and copper by operating at high temperatures (around 1500oC). Lithium and aluminum are typically lost and bonded in slag debris in this procedure. Utilizing secondary procedures, some lithium can be extracted from slag. Due to the necessity to remove poisonous fluorine emissions, modern smelting facilities are pricey, energy-intensive, and have relatively low material recovery rates.

The Second Life of Batteries

For battery and vehicle makers, a second use for used batteries presents an intriguing possibility to lower the cost of EVs and maybe increase profit. Reuse increases battery life and might even replace some new batteries in stationary applications, which lessens the overall environmental effects of battery production.

Some batteries might be repaired so they can be used right away in a different car, potentially prolonging the lifespan of numerous car components. Consequently, working modules and cells can frequently be reassembled when a battery pack fails early to provide reconditioned battery packs for other cars.

Given the size and performance of current automotive batteries, batteries that have been retired from service in a vehicle may still supply a sizable amount of capacity. Batteries lose performance as they are charged and drained, and degradation reduces the amount of stored energy used to power the vehicle, which means that it can go only so far on a single charge. On the other hand, EV batteries might live a second life in less demanding applications. Batteries may last 6 to 10 years in a stationary, low-power application, storing energy from solar panels for off-grid or peak demand-shaving applications. In contrast, the high power requirements of a car make stored energy inaccessible.

The constantly improving costs and performance of new batteries have been a significant impediment to reuse. The performance of new batteries has increased while the price has decreased over an order of magnitude, pricing out used batteries from various applications. Current battery packs’ integrated construction and design, as well as their exclusive management software, restrict component replacement and raise the cost of testing and repurposing.

Recovery of Rare Earth Materials

Along with the value chain for batteries, recycling might reduce the need for new mining, limit the depletion of virgin resources, and lessen the effects on vulnerable populations. For instance, the Democratic Republic of the Congo produces more than 60{bc15fb563bc9e6ea4b4b9214a7065db39a2e1404a7b336cb8ec1271fee783eb0} of the world’s cobalt supply linked to armed conflict, illegal mining, violations of human rights, and destructive environmental practices. Reusing batteries and reformulating cathodes with less cobalt could help minimize reliance on foreign suppliers and improve supply chain security.

Materials recovered from recycled batteries may be a significant and eco-friendly material supply source for batteries in the future. Given a high enough material content ratio to material value, research has demonstrated that effective cathode recycling can be lucrative. More importantly, recycling might offer economically and environmentally advantageous alternatives to making cathode chemicals from virgin materials.

Wrapping Up

After realizing the need for lithium-ion batteries, BatX Energies started recycling the end-of-life lithium-ion batteries to extract rare-earth materials from them. These materials are sent back to the supply chain, encouraging lithium battery companies to produce more batteries without relying on expensive mining procedures, which significantly harm the environment.