The premium screen from CP would be your best bet to separate sand particles from other materials. It acts as a filter often used in producing oil sands, and it enables the user to gather oil products without collecting sand nearby. Such screens would also be used on a smaller scale in most mining and industrial applications, and it would help separate sand from the collected materials.

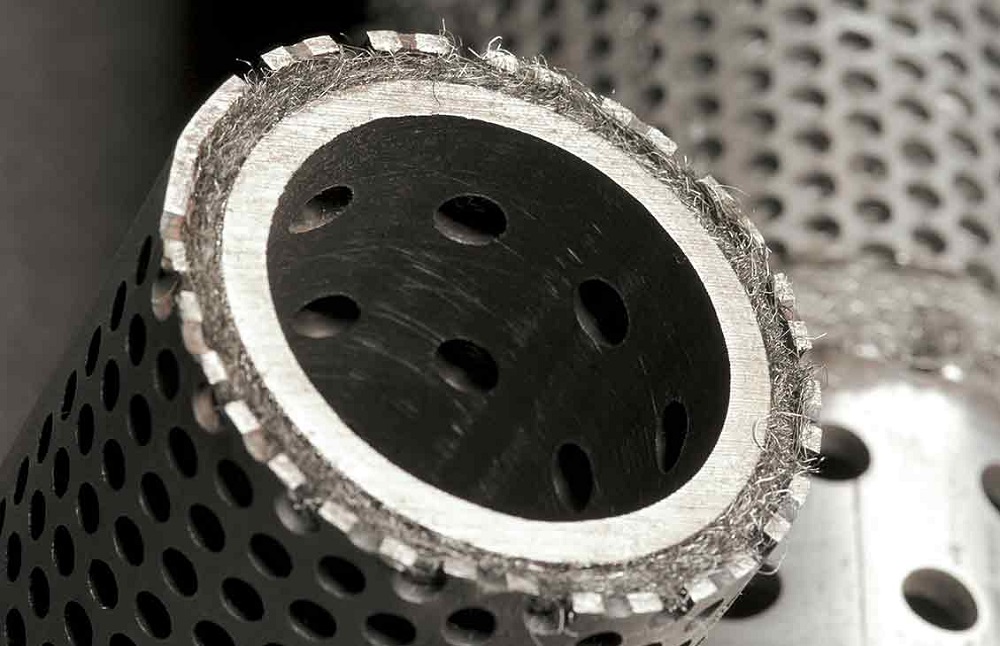

What Is The Sand Screen Manufactured From

The sand screen would be manufactured using metal. However, it could differ in size based on its usage. While the sand screen might fit in a wheelbarrow, other sand screens might expand for a significant length below the earth’s surface.

Applications Of Sand Screen

The most common use of sand screens would be oil production. A majority of crude oil and natural gas supplies have been located underground, and these would be found in regions having conditions similar to a desert. The process entails large drills boring beneath the earth’s surface in such areas for oil collection. It would require the sand screen to line the diameter of the bore. It enables oil and natural gases to pass through while safeguarding the borehole from the sand. It would assist in preventing sand from covering the drills to slow the production rate. It could also hamper the functionality of the drilling equipment.

Stainless Steel For Sand Control Screens

Usually, sand control screens have been manufactured from stainless steel. It assists in holding up the screen holding in unfavourable conditions. Due to the adequate performance of stainless steel compared to other available materials on exposure to crude oil and natural gas makes the perfect material for sand control screens. It could resist chemical corrosion and rust. It assists in enhancing the overall life of the sand control screen.

Various Categories Of Sand Screen

A sand screen would come in different categories based on the size of its holes. It is commonly called mesh. Every screen should be chosen prudently depending on the size of the sand particles in different applications. It would also be selected based on the flow and the thickness of the oil gathered. A significantly large mesh would imply having a considerable quantity of sand slipping through the screen. However, a fine-mesh could slow the production rate and hamper the seeping of desired materials through the net. Most operations would be dependent on the blend of different sizes of the mesh and the screen to gather sand while simultaneously enabling the free flow of the oil into the bore.

The sand control screens would enable workers to block sand particles deep underground where a traditional sand screen might not reach.